The XNX Universal Transmitter is a highly customizable and versatile gas detection solution, supporting multiple sensor types and offering modular input/output options for enhanced flexibility and cost savings․

Overview

The XNX Universal Transmitter is a cutting-edge gas detection solution designed for versatility and reliability in hazardous environments․ It supports a wide range of sensing technologies, including catalytic bead, infrared, and electrochemical sensors, ensuring compatibility with various gas types․ The transmitter’s modular design allows for flexible configuration, with options for different communication protocols such as Modbus and Foundation Fieldbus, enabling seamless integration into existing systems․ Its rugged construction and compact design make it suitable for installation in harsh industrial settings, while its user-friendly interface simplifies operation and calibration․ The XNX Universal Transmitter is certified for use in hazardous areas worldwide, adhering to global safety standards․ It offers advanced features such as remote mounting capabilities and optional explosion-proof enclosures, further enhancing its adaptability․ With its robust performance, ease of use, and comprehensive compatibility, the XNX Universal Transmitter is a reliable choice for gas detection needs across industries, ensuring safety and efficiency in diverse applications․

Product Description

The XNX Universal Transmitter is a advanced gas detection device designed for reliability and flexibility in hazardous environments․ It supports a wide range of sensing technologies, including catalytic bead, infrared, and electrochemical sensors, making it suitable for detecting various gas types․ The transmitter features a modular design, allowing users to choose from different communication protocols such as Modbus and Foundation Fieldbus, ensuring compatibility with diverse systems․ Its compact and rugged construction enables installation in harsh industrial conditions, while the intuitive interface simplifies configuration and calibration․ The XNX Universal Transmitter is certified for use in hazardous areas globally, adhering to international safety standards․ It also offers remote mounting options and explosion-proof enclosures, enhancing its adaptability․ With its robust performance, ease of use, and comprehensive compatibility, the XNX Universal Transmitter is a reliable solution for gas detection across industries, ensuring safety and efficiency in various applications․ The device is supported by a detailed installation manual, providing clear guidelines for optimal setup and operation․

Key Features

The XNX Universal Transmitter offers a range of advanced features that enhance its functionality and versatility․ It supports multiple sensing technologies, including catalytic bead, infrared, and electrochemical sensors, ensuring compatibility with various gas types․ The transmitter’s modular design allows for easy integration with different communication protocols such as Modbus and Foundation Fieldbus, making it adaptable to diverse industrial systems․ Its compact and lightweight construction facilitates easy installation, while the intuitive interface simplifies configuration and calibration․ The XNX is certified for use in hazardous areas worldwide, meeting stringent safety standards․ Additionally, it supports remote mounting options, enabling installation in hard-to-reach locations․ The transmitter’s robust design ensures reliability in harsh environments, and its advanced diagnostics provide real-time monitoring and troubleshooting capabilities․ These features make the XNX Universal Transmitter a highly reliable and efficient solution for gas detection, suitable for a wide range of industrial applications․ Its flexibility and durability ensure optimal performance in demanding conditions․

Installation of XNX Transmitter

The XNX Transmitter offers flexible installation options, including wall and pipe mounting using integral tabs or optional pipe kits, and supports remote mounting for versatility in various industrial environments․

Pre-Installation Requirements

Before installing the XNX Universal Transmitter, ensure the site meets all safety and technical requirements․ Verify the operating environment, including temperature, humidity, and gas type compatibility․ Ensure the power supply matches the transmitter’s voltage requirements, typically 16-32 VDC․ Review the manual to confirm sensor compatibility and mounting options․ Familiarize yourself with local safety regulations and hazardous area certifications․ Prepare all necessary tools and accessories, such as mounting hardware and wiring․ Ensure the transmitter is configured for the specific gas detection application and that calibration gases are available if required․ Finally, read and understand the safety precautions and installation guidelines provided in the manual to ensure a safe and proper setup․

Mounting Options

The XNX Universal Transmitter offers flexible mounting options to suit various installation environments․ It features integral mounting tabs for secure attachment to flat surfaces, Unistrut, or pipes with diameters ranging from 2 to 6 inches (50 to 150mm) using an optional Pipe Mount Kit․ This versatility ensures the transmitter can be installed in multiple configurations, including wall-mounted or remote setups․ For remote mounting in hazardous areas, the transmitter can be paired with a Remote Mounting Kit, providing additional installation flexibility․ The compact design and rugged construction allow it to withstand harsh industrial conditions while maintaining accuracy and reliability․ Proper mounting ensures optimal performance and safety, so consult the manual for detailed diagrams and guidelines to select the most appropriate mounting method for your application․

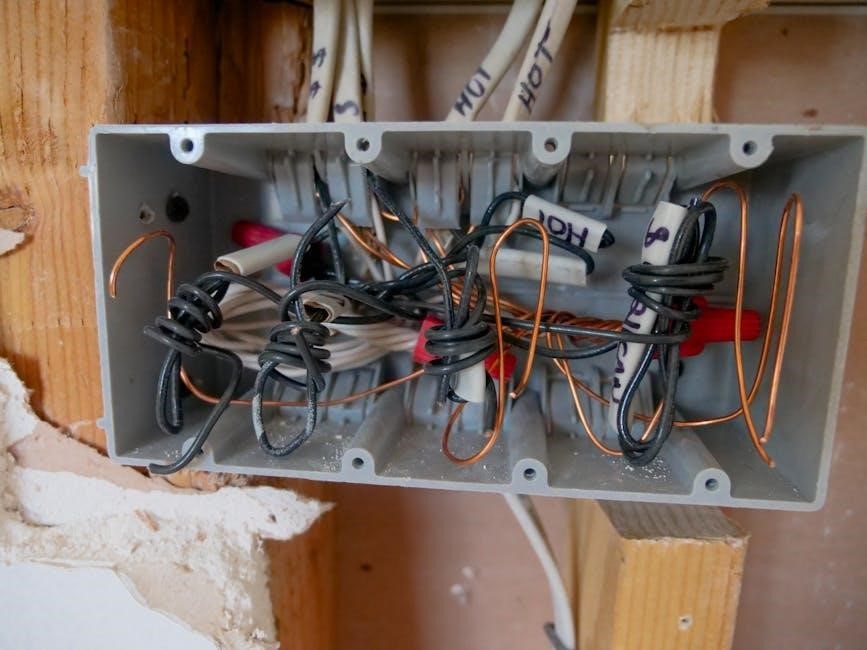

Wiring Configurations

The XNX Universal Transmitter supports various wiring configurations to accommodate different communication and power requirements․ It features multiple communication boards, including relay, Modbus, and Foundation Fieldbus options, allowing for seamless integration with existing systems․ The transmitter’s wiring diagrams, provided in the 2022 manual, detail the connections for power, sensors, and communication interfaces․ Power supply requirements range from 16 to 32 VDC, depending on the sensor type and configuration․ Proper wiring is essential for accurate gas detection and reliable operation․ The manual emphasizes the importance of following the recommended wiring procedures to avoid electrical hazards and ensure compliance with safety standards․ Specific wiring instructions, such as using anti-seize compound on threads, are highlighted to prevent corrosion and maintain signal integrity․ By adhering to the wiring guidelines, users can ensure optimal performance, safety, and longevity of the XNX Universal Transmitter in their gas detection system․

Wiring Diagrams

The XNX Universal Transmitter’s wiring diagrams are detailed in the 2022 installation manual, providing clear visual guidance for proper connections․ These diagrams cover configurations for different personality modules, such as the 2-2-8 MV setup, ensuring compatibility with various system requirements․ The manual includes step-by-step instructions for wiring sensors, power supplies, and communication interfaces, emphasizing the use of anti-seize compound on threads to prevent corrosion․ The diagrams also illustrate remote mounting options and their associated wiring requirements․ By following these diagrams, users can ensure accurate and reliable connections, adhering to safety standards and system specifications․ The wiring diagrams are essential for achieving optimal performance and maintaining the integrity of the gas detection system․ Always refer to the manual for detailed instructions to avoid installation errors and ensure compliance with industry standards․

Power Supply Requirements

The XNX Universal Transmitter requires a DC power supply, with specific voltage ranges depending on the model and sensor type․ For EC and mV versions, the recommended power supply is 16 to 32 VDC, while the Searchpoint Optima Plus and Searchline Excel models operate on 18 to 32 VDC․ The manual emphasizes the importance of using a power supply that meets the device’s voltage and current requirements to ensure proper operation․ It is crucial to comply with hazardous area certifications when selecting the power source․ The transmitter’s power supply should be compatible with the device’s electrical specifications, as outlined in the manual․ Always consult the technical manual for detailed guidelines on power supply selection and installation to maintain safety and performance․ Proper power supply configuration is essential for the transmitter’s reliability and accuracy in gas detection applications․

Remote Mounting Options

The XNX Universal Transmitter offers flexible remote mounting options, allowing installation in locations that may be difficult to access or require separation from the main system․ Using the optional Pipe Mount Kit, the transmitter can be securely mounted to pipes with diameters ranging from 2 to 6 inches (50 to 150mm)․ This kit ensures a stable and secure installation, even in harsh industrial environments․ Additionally, the transmitter can be mounted to flat surfaces or Unistrut systems using its integral mounting tabs, providing versatility in deployment; The manual provides detailed instructions for remote mounting, including hardware requirements and wiring considerations․ Remote mounting is particularly useful in hazardous areas, where it allows the transmitter to be placed in a safe location while maintaining optimal gas detection performance․ Proper installation ensures reliability and accuracy, making remote mounting a practical solution for various industrial applications․ Always follow the manual’s guidelines for remote mounting to achieve a safe and effective setup․

Safety Precautions and Compliance

The XNX Universal Transmitter meets global hazardous area certifications and adheres to industry safety standards․ Adherence to installation and operation guidelines ensures compliance and safe functioning in various environments․

General Safety Information

The XNX Universal Transmitter is designed for safe operation in hazardous environments, but proper installation and use are critical to ensure safety․ Always read and understand the 2022 XNX Transmitter Installation Manual before proceeding with any installation or maintenance tasks․ Adherence to recognized industry standards and local regulations is essential to prevent accidents․ Warnings and cautions outlined in the manual must be strictly followed to avoid potential hazards․ Improper installation or operation can result in malfunction, injury, or environmental risks․ Ensure the transmitter is grounded correctly to prevent electrical hazards․ Proper handling of gas sensors and calibration gases is necessary to avoid exposure risks․ Use only approved accessories and components to maintain safety and performance․ Regular maintenance and inspections are required to uphold safety standards․ The transmitter is certified for use in hazardous areas worldwide, but compliance with local codes is mandatory․ Always ensure personnel involved in installation and maintenance are trained and qualified․ Safety is a shared responsibility, and adherence to guidelines ensures reliable and secure operation of the XNX Universal Transmitter․

Hazardous Area Certifications

The XNX Universal Transmitter is certified for use in hazardous areas globally, ensuring compliance with international safety standards․ It meets stringent requirements for explosive atmospheres, making it suitable for installation in Zone 1 and Zone 2 environments․ The transmitter holds certifications from recognized bodies, ensuring it can operate safely in areas where flammable gases or vapors are present․ Compliance with industry standards such as ATEX, IECEx, and CSA US is guaranteed, providing assurance of its reliability in dangerous environments․ Proper installation in accordance with the 2022 XNX Transmitter Installation Manual is essential to maintain certification validity․ The device’s rugged construction and intrinsically safe design prevent ignition risks, ensuring safe operation in hazardous settings․ These certifications confirm the transmitter’s ability to withstand extreme conditions while delivering accurate gas detection․ Always verify the certifications match the specific hazardous area classification of the installation site to ensure compliance and safety․ The XNX Universal Transmitter’s certifications are a testament to its design excellence and reliability in dangerous environments․

Compliance with Industry Standards

The XNX Universal Transmitter is designed to meet a wide range of industry standards, ensuring its performance, safety, and reliability across various applications․ Compliance with standards such as IEC, CSA, and ATEX guarantees that the device operates efficiently and safely in diverse environments․ These standards cover aspects like electromagnetic compatibility, environmental sustainability, and explosion-proof requirements, providing users with confidence in the transmitter’s durability and functionality․ By adhering to these standards, the XNX Universal Transmitter maintains a high level of quality and consistency, making it a trusted choice for industrial gas detection systems․ The transmitter’s compliance with global standards also simplifies its integration into existing systems, reducing the need for additional modifications․ Furthermore, meeting these standards enhances system reliability and user trust, as it assures that the transmitter performs as expected in critical environments․ Always refer to the 2022 XNX Transmitter Installation Manual to ensure that all industry standards are met during installation and operation, thereby maintaining compliance and ensuring optimal performance․

Calibration and Maintenance

Regular calibration and maintenance of the XNX Universal Transmitter are essential for ensuring accurate gas detection and optimal performance․ Follow the 2022 XNX Transmitter Installation Manual for detailed procedures and guidelines․

Calibration Procedures

Calibration of the XNX Universal Transmitter is critical for ensuring accurate gas detection and reliable performance․ The process involves zero calibration and span calibration, which must be performed using certified calibration gases․ Zero calibration sets the baseline for the sensor in a gas-free environment, while span calibration adjusts the sensor response to the target gas concentration․ The transmitter’s interface allows for easy adjustment of these settings, ensuring precise measurements․ Refer to the 2022 XNX Transmitter Installation Manual for detailed step-by-step instructions and recommended calibration intervals․ Improper calibration can lead to inaccurate readings, so adherence to the manual’s guidelines is essential․ Additionally, the manual provides troubleshooting tips for common calibration issues, such as sensor drift or incorrect gas responses․ Regular recalibration is necessary to maintain accuracy, especially in harsh or changing environmental conditions․ Always use the correct calibration tools and follow safety protocols to ensure optimal transmitter performance; Consulting the manual is the best way to ensure compliance with calibration best practices․

Routine Maintenance Tasks

Routine maintenance is essential to ensure the XNX Universal Transmitter operates efficiently and accurately․ Regularly inspect the sensor for contamination or damage, and clean it according to the manual’s instructions․ Check the wiring and connections for signs of wear or corrosion, and replace any damaged components promptly․ Perform visual inspections of the transmitter housing to ensure it is free from dust, dirt, or corrosion․ Lubricate moving parts if necessary, using anti-seize compound to prevent corrosion․ Additionally, verify that all software and firmware are up to date, as updates often include performance improvements and bug fixes․ Refer to the 2022 XNX Transmitter Installation Manual for specific maintenance schedules and procedures․ Regular maintenance not only extends the lifespan of the transmitter but also ensures reliable gas detection and compliance with safety standards․ Always follow the manual’s guidelines to maintain optimal performance and safety․

Troubleshooting Common Issues

Troubleshooting the XNX Universal Transmitter involves identifying and resolving common issues promptly to ensure continuous operation․ Start by checking the power supply to confirm it meets the required voltage range․ If the transmitter is not powering on, verify the wiring connections and ensure there are no loose or damaged cables․ For sensor-related issues, inspect for contamination or blockage, and perform a zero calibration if necessary․ If communication errors occur, check the Modbus or Foundation Fieldbus connections and ensure all settings are correctly configured․ Review the 2022 XNX Transmitter Installation Manual for detailed troubleshooting guides tailored to specific problems․ Regularly updating firmware and software can also resolve operational issues․ Always follow the manual’s safety precautions during troubleshooting to avoid potential hazards․ By systematically addressing these common issues, users can quickly restore the transmitter to optimal functioning and maintain reliable gas detection․

Software Updates and Firmware

Regular software updates and firmware installations are essential for maintaining the optimal performance of the XNX Universal Transmitter․ These updates ensure the device operates with the latest features, security patches, and performance enhancements․ Honeywell provides periodic firmware releases to improve functionality, resolve potential issues, and enhance compatibility with various sensors and communication protocols․ Users can download the latest firmware from Honeywell’s official website or through authorized distributors․ The installation process is straightforward and can be performed using a PC or handheld device connected to the transmitter․ Always refer to the 2022 XNX Transmitter Installation Manual for detailed step-by-step instructions to avoid errors during the update process․ It is crucial to follow safety protocols and backup procedures to prevent data loss or device malfunctions․ Updated firmware ensures the transmitter remains compliant with industry standards and operates efficiently in hazardous environments․ Troubleshooting tips for firmware-related issues are also provided in the manual for quick resolution․

The XNX Universal Transmitter is a versatile and reliable gas detection solution, offering compatibility with multiple sensing technologies and modular design for flexibility․ It supports easy installation with various mounting options, including wall and pipe configurations, and requires proper calibration for accurate performance․ The transmitter is certified for use in hazardous areas and complies with industry safety standards․ Regular maintenance and adherence to troubleshooting guidelines ensure optimal functionality and longevity․ Referencing the 2022 manual is crucial for detailed installation, operation, and maintenance instructions․ The manual emphasizes safety precautions and provides comprehensive guidance for sensor mounting, wiring, and configuration․ By following the outlined procedures, users can ensure reliable gas detection and system performance․ The XNX Universal Transmitter is a robust solution for industrial and environmental monitoring applications, offering enhanced safety and efficiency․ Always consult the official manual or contact Honeywell’s customer support for additional assistance․

References to the 2022 Manual

The 2022 XNX Transmitter Installation Manual is a comprehensive guide providing detailed instructions for the installation, operation, and maintenance of the XNX Universal Transmitter․ It includes essential safety information, warnings, and cautions to ensure compliance with industry standards and regulations․ The manual covers key topics such as sensor mounting, wiring configurations, calibration procedures, and troubleshooting common issues․ It also outlines the transmitter’s technical specifications, communication options, and certification details for hazardous area use․ Users are advised to read the manual thoroughly before proceeding with any installation or maintenance tasks to ensure proper setup and functionality․ The document is available for free download in PDF format and serves as the primary reference for understanding and working with the XNX Universal Transmitter․ By following the manual’s guidelines, users can optimize the transmitter’s performance and ensure reliable gas detection in various environments․ Regular updates and revisions ensure the manual remains relevant and accurate for all applications․ Always refer to the official 2022 manual for the most up-to-date information and procedures․

Customer Support and Contact Information

For any inquiries or assistance regarding the XNX Universal Transmitter, customers can reach out to Honeywell’s dedicated customer support team․ The 2022 manual provides contact details for technical support, including phone numbers, email addresses, and regional office locations․ Additionally, Honeywell offers online resources such as FAQs, troubleshooting guides, and software updates to help users resolve issues independently․ Customers can also access training materials and certification programs to enhance their understanding of the XNX Transmitter․ Emergency support is available for critical situations, ensuring minimal downtime and optimal system performance; Honeywell’s commitment to customer satisfaction is reflected in their comprehensive support services, designed to address all installation, operation, and maintenance needs․ For further assistance, users are encouraged to visit Honeywell’s official website or contact their local distributors․ The support team is ready to provide expert guidance and ensure the XNX Transmitter operates efficiently in any application․